您當前的位置:檢測資訊 > 生產品管

嘉峪檢測網 2025-06-17 21:20

Most mistakes regarding the programming and operation of typical steam sterilizers are related to the basic principles of steam sterilization.

常見蒸汽滅菌柜的大多數程序和操作錯誤都與蒸汽滅菌的基本原理有關。

1. Containers with closed valves, empty glass bottles with tightened screw caps or secured aluminum foil are placed in the sterilizer.

滅菌柜中放入關閉的閥門、旋緊瓶蓋或緊扣鋁蓋的空玻璃瓶。

As a result, steam cannot directly contact the inside surfaces and sterilization does not occur. This problem can be resolved by assuring that all items in the sterilizer have a way for the steam to get in and the air to get out. If there is uncertainty about whether an item’s configuration, set-up, packaging, or orientation will allow adequate steam penetration, a thermocouple, chemical and/or biological indicator can be placed inside the item to be certain.

這樣, 蒸汽就不能直接接觸到內表面,無法進行滅菌。 這一問題可通過確保滅菌柜中的物品有蒸汽進入和空氣排出的通道來解決。 如果不確定物品的配置、設置、包裝或方位是否允許充分的蒸汽穿透,那么可以通過在物品內部放置熱電偶、化學和/或生物指示劑來確定。

2. Pouched and/or heavily wrapped items are tightly packed in the chamber.

袋裝和/或嚴密包裹的物品緊實地裝載在腔室內。

As a result, air may remain trapped in the items after the preconditioning phase and prevent sterilization. Items should not be overwrapped, and sufficient space should be maintained between load items. The preconditioning vacuum and pressure pulses must be set correctly to attain complete air removal from the load. Typically, four (or more) preconditioning vacuum pulses should be programmed to reach at least 28 in (711 mm) Hg vacuum ((1.0 psia or 6.9 kPa (absolute)) to assure sufficient air removal for worst case loads. Some very dense loads may require a short (2 to 5 min) hold phase at peak preconditioning vacuum to allow time for trapped air to be removed. Preconditioning pressure pulses should be programmed for 3 to 5 psig ((21 to 34.5 kPa (gauge)). Higher pressures set for prevacuum pressure pulses can result in an excessive amount of superheat and difficulties with temperature stabilization during the first few minutes of the exposure phase.

這樣, 預真空階段后空氣可能仍然滯留在物品中,阻礙了滅菌。 物品不應過度包裹,且應在物品間留有足夠的空間。 預真空和壓力脈動必須正確地設定,以完全排除裝載內的空氣。 通常, 應該程序設定達到 28 in (711 mm)汞柱((1.0 psia or 6.9kPa (絕對壓力))真空且四次(及以上)預真空脈動,以確保最差裝載情況下空氣排除充分。 有些非常密集的裝載在預調節真空峰值時可能需要一段較短( 2-5min)的保持時間,從而排除滯留的空氣。 預調節真空脈動應設定為 3~5 psig ((21~34.5 kPa (表壓))。 預調節壓力脈動可能造成暴露階段前幾分鐘時的過熱和溫度穩定困難。

3. Heavier items are placed on top shelves.

較重的物品置于貨架頂層。

Water droplets and/or stains are observed on the outside of wrappers of items placed on the mid to lower shelves after the sterilization cycle is complete. Because the items are not dry, they cannot be aseptically removed from the sterilizer. Condensation is the natural result of steam contact with the cooler surfaces of the load. The condensate will fall from shelf to shelf. The denser the load item, the more condensate is created. Therefore, place heavier items on the bottom shelf. In addition, consider placing a cotton sheet or lint free towels on each sterilizer loading cart shelf prior to loading to allow the condensate to be absorbed. This also aids in drying. As the condensate wicks into the sheet or lint free towels, the condensate surface area is greatly increased and evaporates much more rapidly during the drying phase than the same amount of condensate in a droplet or a puddle.

滅菌循環結束后, 置于中間和低層的物品包裝外表面可以看到水滴和/或污跡。 由于物品不是干燥的,不能無菌地從滅菌柜中取出。 冷凝是蒸汽接觸物品冷表面時的自然結果。冷凝水會從貨架上滴下。物品的放置越密, 產生的冷凝水越多。 因此, 應將更重的物品放置于低層。 另外,在裝載前考慮在各滅菌裝載貨架上放置純棉布或無絨毛巾來吸收冷凝水。這也有助于干燥。由于冷凝水浸入棉布或無絨毛巾,冷凝水表面積大大增加, 與同量冷凝水滴相比干燥階段的氣化速率也大大提高。

4. Load is too dense or items are positioned incorrectly in the load.

裝載過于密集或物品在裝載中擺放位置不對。

As a result, wet or damp items are observed at the end of the cycle. Wrapped items positioned so that condensate is allowed to collect will not be dried. Items should be positioned so that the condensate is allowed to flow downward. Items (wrappers, pouches, filters, or other porous biological barriers) that remain wet at the end of cycle cannot prevent contamination of the load when removed from the sterilizer. As the load cools outside the sterilizer, the water in the wrapper will be drawn into the wrapped item. Any contamination that is present in the environment can be drawn through the sterile barrier along with the water. There are numerous other possible causes for wet loads.The most common are:

因此, 循環結束時發現物品變得潮濕。 放于會收集冷凝水的位置的包裹物品不會被干燥。 物品的放置應允許冷凝水向下流動。 物品(包裹、 呼吸袋、過濾器或其它多孔生物濾膜) 由于在循環結束時仍是濕的,在從滅菌柜取出時不能避免裝載的污染。由于在滅菌柜外冷卻,包裹上的水會浸入到被包裹的物品中。 任何環境中的污染源都可能隨水一起穿過無菌屏障。 還有許多其它原因可能會造成裝載潮濕,最常見的是:

a. Insufficient drying vacuum level or time programmed

程序設計干燥真空水平或時間不夠

b. Rubber or plastic items in pouches (i.e., rubber stoppers, plastic tubing) may require additional drying (a pulsed air or heated pulsed-air drying process is recommended for these items)

袋裝的橡膠或塑料制品(如橡膠塞、塑料管)可能需要額外的干燥( 對于這些物品,推薦采用脈動空氣或脈動熱空氣干燥工藝)

c. Wet steam

濕蒸汽

While there is no single solution to eliminating wet loads, it’s likely that experimenting with drying time, repositioning items, reducing load density, modifying cycle settings, and investigating steam quality will resolve the problem.

由于沒有哪個方案一定能有效消除裝載潮濕,很可能通過試驗干燥時間、重新放置物品、降低裝載密度、改進循環設置和調查蒸汽質量可以解決這個問題。

5. Pouches are placed flat on the sterilizer shelves or stacked on top of one another.

呼吸袋平放于滅菌柜貨架上或疊放在一起。

As a result, pouches may have water droplets inside and cannot be aseptically removed from the sterilizer. Typical cause is when the condensate naturally created when steam penetrates the pouch and contacts the surface of the item within is not removed during the post-conditioning drying phase. Pouches should be spaced properly and placed in rack that holds the pouch on its edge (as figure) to prevent pooling of the condensate inside the pouch. Pouches should not be placed flat on the sterilizer shelf. Pouches should not be overloaded. Remember that more mass means more condensate.

這樣, 呼吸袋可能會有水滴在內部, 不能從滅菌柜中無菌地取出。 通常原因是蒸汽穿透呼吸袋和接觸物品表面時會自然形成冷凝水,這些冷凝水在滅菌后干燥階段沒能除去。 呼吸袋之間應留有足夠的空隙,并放置于擱架上(如圖),以防止呼吸袋內部冷凝水聚集。呼吸袋不應平放于滅菌架上。 呼吸袋不應疊放。 記住, 物品越多,冷凝水越多。

Sufficient drying vacuum level and time should be programmed to allow for complete evaporation of the condensate. Wet steam should be corrected. Double pouching may require additional prevacuum pulses with dwell time at maximum vacuum and increased drying time. Doubled pouches should never be assembled so that the items inside cannot be seen.

Pouch flaps should not be folded over.

程序應設定足夠的干燥真空水平和時間, 使冷凝水完全氣化。 濕蒸汽應調節為飽和蒸汽。 雙層呼吸袋可能需要額外的預真空脈動, 在最大真空時保持一定時間并增加干燥時間。 雙層呼吸袋絕不應以看不到內部物品的方式組裝。 袋口不應折疊起來。

6. Liquids in vented containers are placed in a deep pan to catch boil-over (slow exhaust cycle).

通氣容器中的液體放置于深托盤內,以收集沸溢的液體(在緩慢排氣循環)。

The pan will hold water and it will hold air. The steam cannot contact the surfaces within the pan because of the trapped air, and they will not be sterilized. The solution is to eliminate the pan and adjust the sterilizer slow exhaust rate to prevent boil-over. A shallow pan, less than 1” (25 mm) deep, can be used in the event that a small amount of boil-over cannot be eliminated

by adjusting the slow exhaust rate.

托盤會容納水也會滯留空氣。 蒸汽不能在托盤內受滯留空氣的阻礙而不能接觸到表面,因此達不到滅菌效果。 解決方法是去除托盤,調試滅菌柜的緩慢排氣速率,防止沸溢。 淺托盤,少于 1” (25 mm)深, 可用于少量沸溢不可避免時的情況。

7. “Overcooked” Media

培養基“加熱過久”

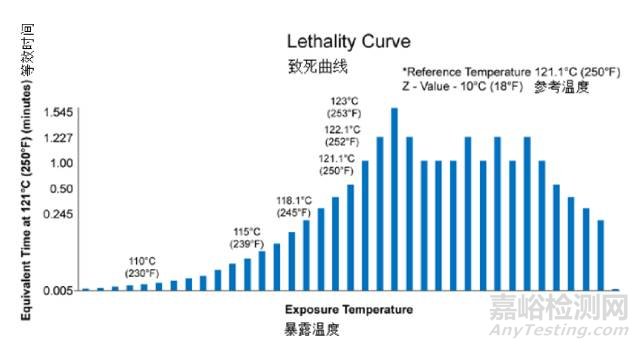

Over sterilization of media will caramelize the sugars and render the media useless. The typical overkill approach is not recommended for sterilization of media. The exposure phase should be programmed to achieve the desired SAL and no longer. Use of a load probe and F0 exposure control is recommended for sterilization of media in containers larger than 100 ml (3.4 oz). As illustrated in Figure 8, F0 is a calculation of the equivalent exposure at temperatures other than 121.1°C (250°F). As the liquid is heated, the calculated F0 (from the load probe temperature) is accumulated until the selected F0 exposure value (minutes) is achieved, at which point the cycle proceeds to the exhaust/cooling phase. For example, on the graph, the kill rate on the same population of organisms is half as effective at 118°C (245°F) as at 121°C (250°F). Therefore, at 118°C (245°F), it will require twice the exposure time to kill the same number organisms.

培養基過度滅菌會使糖分焦化,使培養基失效。培養基滅菌不推薦采用典型的過度殺滅方法。 程序應設計暴露階段, 以恰好達到所需的 SAL。 在大于100 ml (3.4 oz)的容器內的培養基推薦采用裝載探頭和 F0 值暴露控制滅菌。 如圖 8 所示, F0 是 121.1°C(250°F)以外的溫度下計算等效暴露。 隨著液體被加熱, 計算出的 F0(從裝載探頭溫度) 逐漸累積,直到達到所選的 F0 暴露值(分鐘), 此時循環進行至排氣/冷卻階段。例如,從圖上可以看出, 在 118°C(245°F)時同樣數量微生物的殺死率是在 121°C(250°F)時的一半。 因此,在 118°C (245°F)時,需要兩倍的暴露時間才能殺死同樣數量的微生物。

Figure 8. F0 as a function of temperature.

圖 8. 溫度函數 F0

A common formula for calculating the F0 value is:

計算 F0 值的常見公式是:

where:

其中,

• L is lethal rate of bacterial spores

• L 是細菌孢子致死率

• t is exposure time, [s]

• t 是爆熱時間, [s]

• T is exposure temperature, [°C]

• T 是爆熱溫度, [°C]

• z is a constant, [°C]

• z 是常數, [°C]

The constant z describes the slope of the thermal death curve. The widely accepted value for z is 10°C (18°F) in steam sterilization.

常數 z 描述熱力致死曲線的斜率。 對于蒸汽滅菌,廣泛認同的 z 值是 10°C (18°F)。

8. Using cold water for vacuum pump that is too hot.

真空泵使用的冷卻水過熱

As a result, the vacuum pump may not be able to reach 1.0 psia (6.9 kPa). The heart of the prevacuum sterilizer is the water-ring vacuum pump. The efficiency and maximum vacuum capability of a water-ring vacuum pump are adversely affected by higher water temperatures typically encountered during the summer months. During operation, the water within the pump is heated by mechanical friction and heat energy from the sterilizer chamber. If the temperature of the water inside the pump reaches 39°C (102°F) during the preconditioning or post conditioning vacuum peak, the water inside the pump will boil at ≤ 1.0 psia (6.9 kPa) and cause cavitation. In this case, the recommended preconditioning vacuum level of 1.0 psia (6.9 kPa) cannot be achieved in the sterilizer chamber. A common “work-around” for this situation is to change the set point of the prevacuum pulses to a level that can be achieved. Insufficient air removal can be the result unless the number of vacuum pulses is increased, causing longer cycle times and less effective air removal. Internal pump temperatures higher than 39°C (102°F) are often observed during the summer months if the water supplied to the pump is not cooled. Chilled water is ideal, but typically too expensive to use in a sterilizer vacuum pump arrangement in which the water flows from the vacuum pump to drain. The recommended solution is a recirculation/cooling system for the vacuum pump water that uses chilled water in a closed loop heat exchanger. This configuration is eco-friendly as it saves a significant amount of water. In addition, the vacuum pump efficiency is not subject to seasonal water temperature fluctuations.

這樣,真空泵可能達不到 1.0 psia (6.9 kPa)。真空滅菌的核心是水環真空泵。在夏季期間經常發生水溫過高,這可能會對水環真空泵的效能和極限真空度造成不良影響。在操作期間,泵內的水由于機械摩擦和滅菌腔室的熱量被加熱。如果預調節或后調節真空期間泵內的水溫達到 39°C (102°F),泵內的水在≤ 1.0 psia (6.9 kPa)真空下會沸騰,造成氣蝕。這種情況下,滅菌腔室內就達不到推薦的真空水平1.0 psia (6.9 kPa)。這種情況常見的“應對措施”就是改變預真空脈動的真空設定值,降為可達到的水平。這可能造成排氣不足, 除非增加真空脈動次數,從而造成循環周期延長,排氣效率下降。 如果真空泵進水未經冷卻,夏季時經常發現泵內溫度高39°C(102°F)。 冷凍水是理想選擇,但對于滅菌柜真空泵來說成本過高,因為真空泵的出水直接排放。 推薦措施是真空泵配循環冷卻水系統,采用冷凍水和閉路循環換熱器。 這種配置可節省大量的水, 經濟環保。此外,真空泵效率不受水溫季節性波動的影響。

9. Load probe is available, but not used.

有裝載探頭但沒有使用。

Most modern sterilizers include (optional) an RTD load probe and F0 exposure control for use in liquids sterilization, but many times the probe is not used. If equipped with a load probe, the exposure can be controlled by the temperature of the liquid rather than the temperature in the drain line. Without the load probe, the temperature of the liquid is not known and can only be estimated, resulting in inadequate (non-sterile) or excessive F0 (overcooked). The load probe should be placed in a container of water approximating the volume of the largest volume of liquid being sterilized. Load probe control/F0 must then be selected in the sterilizer control settings.

多數現代滅菌柜配備(可選)了一個 RTD 裝載探頭和 F0 暴露控制,用于液體滅菌的控制,但是許多情況下這一探頭都沒有被使用。 如果配備了裝載探頭, 暴露可以依據液體溫度來控制,而不是排放管路內的溫度。 如果沒有裝載探頭, 液體溫度是未知的,只能估算, 因此造成滅菌不充分(非無菌)或過度( 加熱過久)。裝載探頭應置于含水容器內,容器內盛水體積約為待滅菌液體的最大體積。 裝載探頭控制/F0必須在滅菌柜控制設置中選擇。

10. Pressure/vacuum rate control is available, but not used.

卸壓/抽真空速率控制可用,但沒有使用。

Most modern sterilizers include (optional) rate control for the vacuum and pressure ramps, but many times the rate control is not used. When no pressure rate control is applied steam will enter the chamber at maximum velocity during the preconditioning pressure pulses, which creates a superheat problem and EN285 compliance problems as discussed earlier. Slowing the pressure rate allows time for superheat to dissipate during the ramp up.

多數現代滅菌柜具備(可選) 抽真空和卸壓速率的控制功能,但許多情況下該速率控制并沒有被使用。 如果沒有采用卸壓速率控制,在預調節卸壓階段,蒸汽將以最大速率進入腔室,從而造成過熱的問題和 EN285 符合性問題。 減緩卸壓速率使卸壓過程中的過熱有時間分散。

When no vacuum rate control is applied the chamber will depressurize at the maximum rate of the vacuum pump. The typical problem associated with this is burst pouches. Slowing the vacuum rate allows time for the pouch internal pressure to equilibrate and prevents bursting during the preconditioning and post conditioning vacuum phases.

如果沒有采用抽真空速率控制, 腔室將以真空泵的最大速率形成真空。這造成的常見問題是爆袋。在預調節和后調節抽真空階段, 減緩抽真空速率使呼吸袋內部壓力有時間平衡,并防止爆袋。

others:

其他注意事項:

Steam sterilizers typically have a steam jacket to insulate the chamber and improve temperature distribution. When a steam jacket is present, it is ordinarily operated at lower steam pressure and temperature than the chamber to avoid superheat.

蒸汽滅菌柜通常有一個蒸汽夾套來隔離腔體并提高溫度分布。為避免過熱,夾套的蒸汽操作壓力和溫度通常比腔體要低。

Pipe slopes should be adequate to promote drainage and condensate removal

管路有一定的坡度以利于污水和冷凝水的排放。

Welds should meet applicable materials and joining standards

焊接應滿足適用的材料以及焊接標準。

If the incoming steam pressure is above the manufacturer's recommendations, additional valves (e.g., modulating steam, pressure reducing, pressure relief, shut-off) should he considered.

如果進口蒸汽壓力超出供應商的建議值,應當考慮使用其他閥門(如蒸汽調節閥,減壓閥,泄壓閥,截流閥)。

An appropriate thermostatic steam trap combined with floating ball should be used to quickly remove large quantities of air and/or condensate from the chamber.

為了快速移除腔體中大量空氣和/或冷凝水,應當選用一個合適的恒溫式疏水閥以及浮球。

來源:GMP辦公室